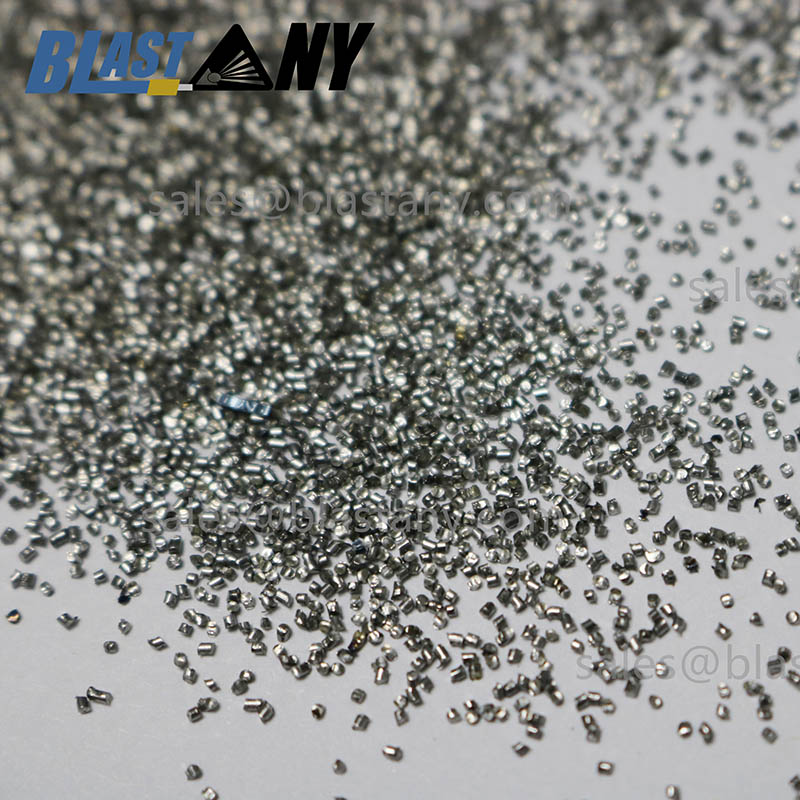

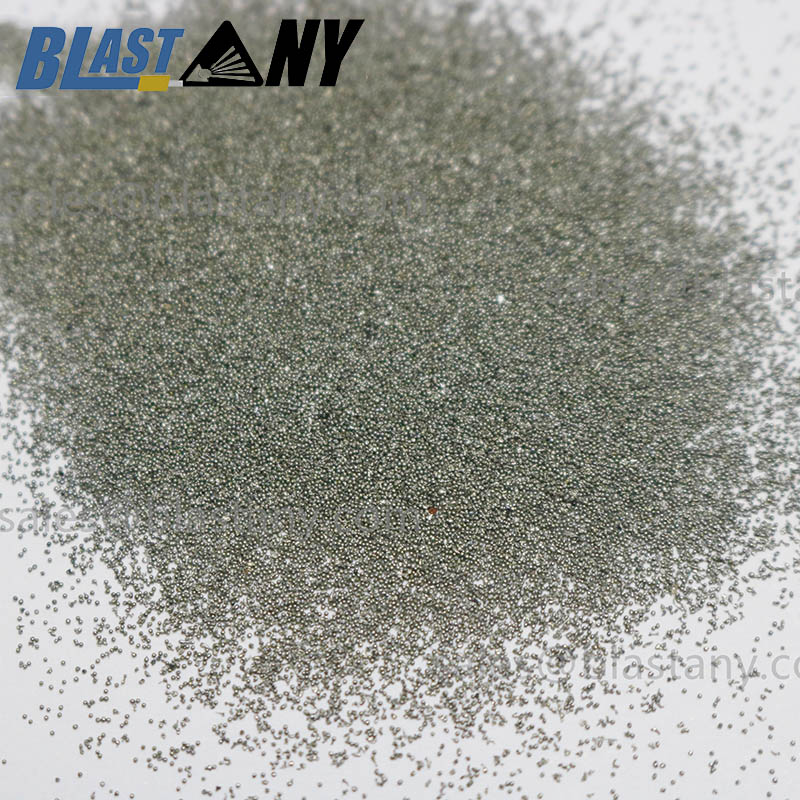

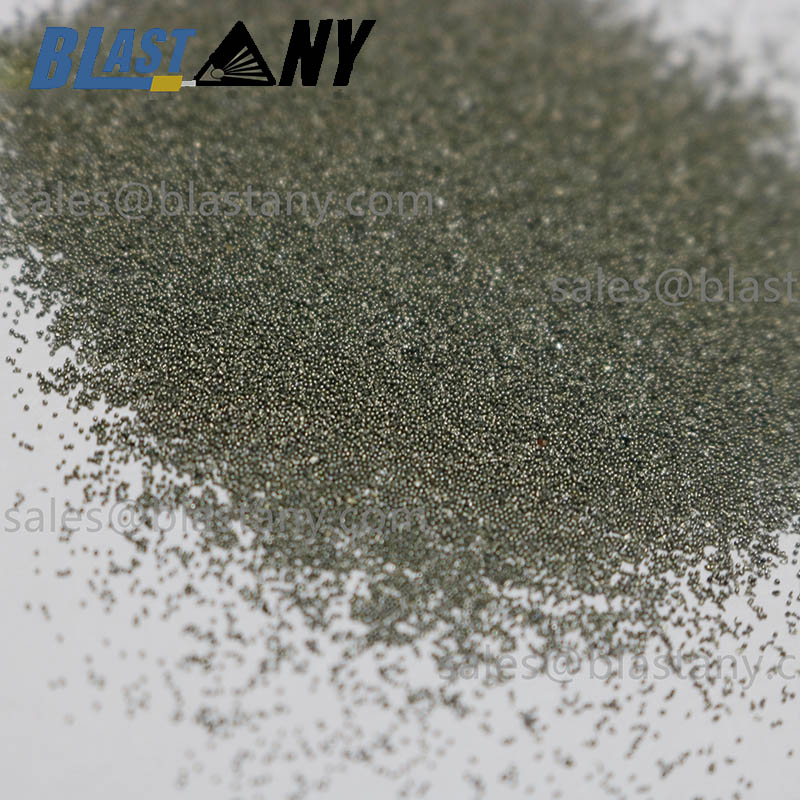

Tembakan baja tahan karat kanthi teknologi atomisasi

Lapangan Aplikasi

1.Permukaan finishing saka aluminium seng die casting lan lumahing reresik saka aluminium wedhi casting. uyuh lumahing marmer Ponggawa lan polishing. Ngresiki lan ngrampungake skala oksida permukaan casting baja paduan dhuwur, blok mesin alloy aluminium lan bagean casting die gedhe liyane, perawatan efek permukaan marmer lan perawatan antiskid.

2.Aluminium seng die casting, reresik lumahing casting tliti, lumahing roughening sadurunge nutupi khusus, olahan semprotan polishing saka profil aluminium kanggo mbusak garis extrusion lumahing, olahan semprotan polishing saka lumahing pipe aluminium tembaga, lan olahan semprotan polishing wadhah stainless steel lan tutup.

3. Ngresiki alat casting kadhemen, kromium plating mati kanggo forging mati lan ban, ndandani tutup pump saka supercharger engine automobile, ngiyataken pindah tliti lan spring saka wiwitan, lan semprotan polishing lumahing wadhah stainless steel.

4.Aluminium zinc die casting, kotak mesin sepeda motor, kepala silinder, karburator, cangkang pompa bahan bakar mesin, pipa intake, kunci mobil. Lumahing profil roda casting tekanan rendah kudu di resiki lan rampung sadurunge dicet. Rampung lumahing lan reresik saka tembaga aluminium stainless steel stamping bagean, investasi casting bagean stainless steel, etc.

Parameter teknis

| Proyek | 304 Kualitas | 430 Kualitas | |

| Komposisi kimia% | C | 0.08-1.0 | <0.2 |

| Si | 0.4-1.2 | <1.5 | |

| Mn | 0.35-1.2 | 0.8-1.2 | |

| S | <0.05 | <0.05 | |

| P | <0.05 | <0.05 | |

| Cr | 15-16.5 | 15-17 | |

| Ni | 5-8% | 0 | |

| Kekerasan | HRC40-50 | HRC35-50 | |

| Kapadhetan | 7,00 g/cm3 | ||

| Struktur mikro | austenit | ferit | |

| Penampilan | Bunder Partikel berongga = 0% Partikel berongga = 0% | ||

| Jinis | 14-18# / 16-20# / 20-25# / 25-30# / 30-40# / 40-70# / 70-140# / 140-270# | ||

| Packing | Saben ton ing Pallet kapisah lan saben ton dibagi ing paket 25KG. | ||

| Daya tahan | 27000~28000 kaping | ||

| Kapadhetan | 7,0 g/cm3 | ||

| Aplikasi | Utamane digunakake kanggo deburring lan permukaan finishing aluminium die casting, zinc alloy die casting lan magnesium alloy die casting; finishing lumahing casting tliti, casting stainless steel lan pemblokiran malang; nggawe kaca, reresik lumahing lan macem-macem pretreatment cetakan die casting. | ||

Aplikasi

| JENIS | Dianjurake orane katrangan saka nggunakake |

| 14-18# | Ngresiki alat casting kadhemen, kromium plating mati kanggo forging ban, ndandani tutup pump saka mobil engine supercharger, ngiyataken pindah tliti lan spring saka wiwitan, lan semprotan polishing lumahing wadhah stainless steel. |

| 16-20# | Aluminium seng die casting, reresik lumahing casting tliti, lumahing roughening sadurunge nutupi khusus, olahan semprotan polishing saka profil aluminium kanggo mbusak garis extrusion lumahing, olahan semprotan polishing saka lumahing pipe aluminium tembaga, lan olahan semprotan polishing wadhah stainless steel lan tutup. |

| 20-25# | Aluminium zinc die casting, kotak mesin sepeda motor, kepala silinder, karburator, cangkang pompa bahan bakar mesin, pipa intake, kunci mobil. Lumahing profil roda casting tekanan rendah kudu di resiki lan rampung sadurunge dicet. Rampung lumahing lan reresik saka tembaga aluminium stainless steel stamping bagean, investasi casting bagean stainless steel, etc. |

| 25-30# | Aluminium seng die casting permukaan finishing, aluminium wedhi casting reresik lumahing. Lumahing marmer buatan disemprotake lan dipoles. |

| 30-40# | Saliyane fungsi wg40, lumahing casting stainless steel Gamelan lan nggoleki. Pengobatan descaling saka tempa baja paduan. efek finishing lumahing marmer Ponggawa lan perawatan antiskid. |

| 40-70# | Kulit oksida permukaan casting baja paduan dhuwur, blok mesin paduan aluminium lan bagean die casting liyane sing reresik lan finishing, perawatan efek permukaan marmer lan perawatan anti-selip. |

| 70-140# 140-270# | Lumahing casting baja kawangun wis deaerated sadurunge nutupi, hub wheel mobil, perawatan Nihan engine, produk granit lan langkah marmer roughening lan perawatan anti-gondhelan. |

Granularity

| LayarNO. | Ukuran layar mm | In | 14-18 | 16-20 | 20-25 | 25-30 | 30-40 | 40-70 | 70-140 | 140-270 |

| 14 | 1.4 | 0,0555 |

|

|

|

|

|

|

|

|

| 16 | 1.18 | 0,0469 |

|

|

|

|

|

|

|

|

| 18 | 1 | 0,0394 |

|

|

|

|

|

|

|

|

| 20 | 0.85 | 0,0331 |

|

|

|

|

|

|

|

|

| 25 | 0.71 | 0,0278 |

|

|

|

|

|

|

|

|

| 30 | 0.6 | 0,0234 |

|

|

|

|

|

|

|

|

| 35 | 0.5 | 0,0197 |

|

|

|

|

|

|

|

|

| 40 | 0.425 | 0.0165 |

|

|

|

|

|

|

|

|

| 50 | 0.3 | 0,0117 |

|

|

|

|

|

|

|

|

| 70 | 0.212 | 0,0083 |

|

|

|

|

|

|

|

|

| 100 | 0.15 | 0,0059 |

|

|

|

|

|

|

|

|

| 140 | 0.106 | 0,0041 |

|

|

|

|

|

|

|

|

| 270 | <0.05 | <0.0019 |

|

|

|

|

|

|

|

|

Kategori produk