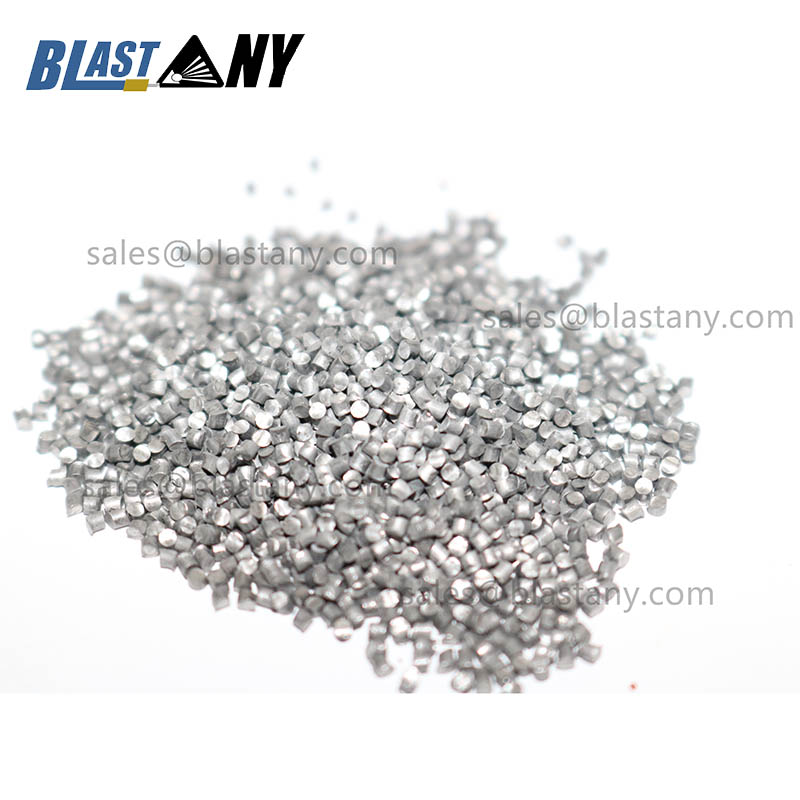

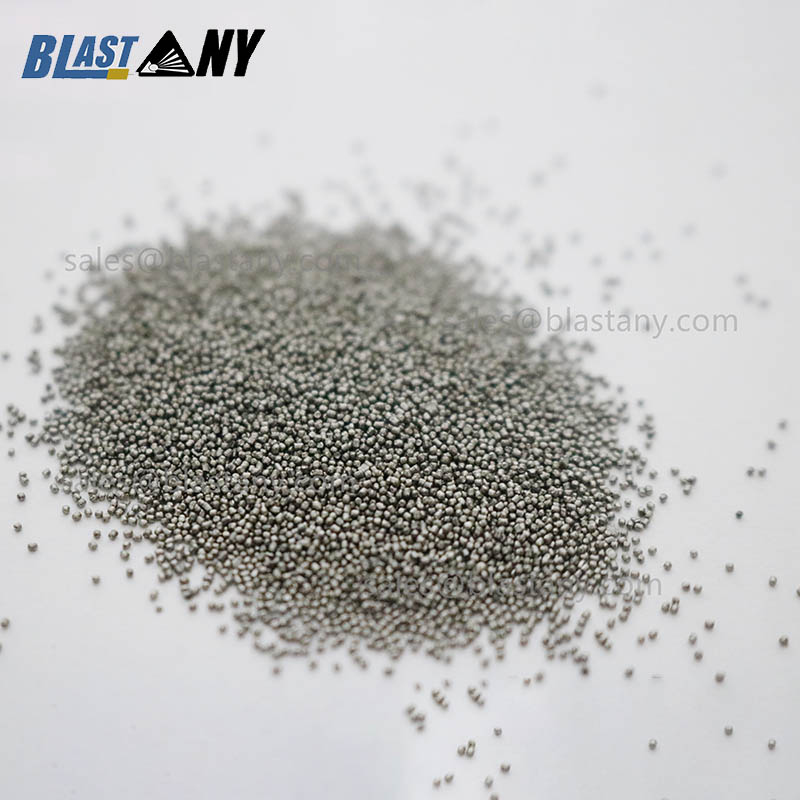

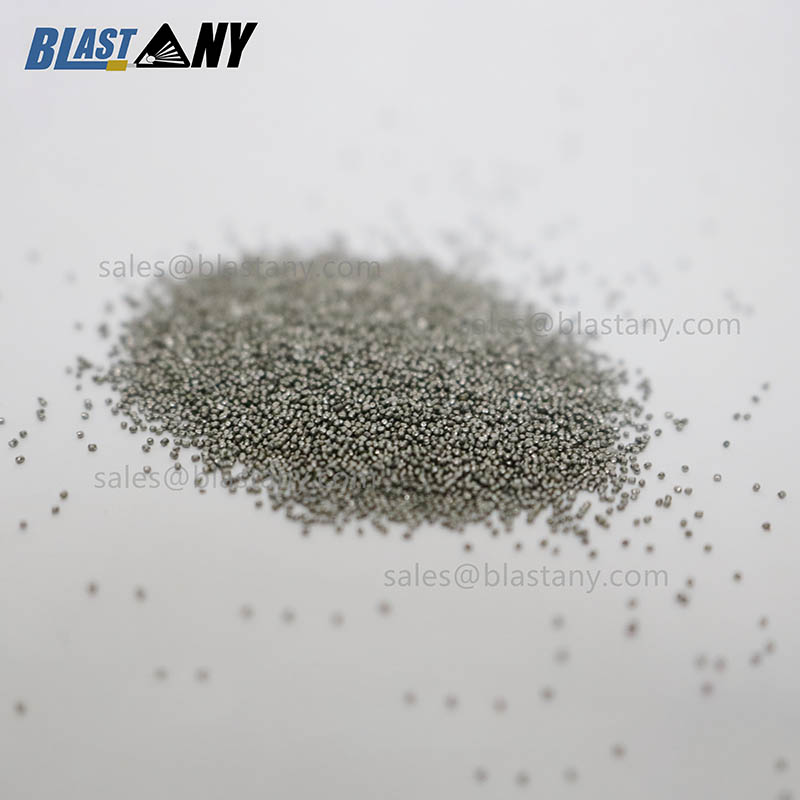

Dhuwur kekuatan lemes tahan Cut Wire Shot

Jenis tembakan pemotong kawat baja

0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Lingkup aplikasi saka pil nglereni kabel

1. Steel wire shot cutting strengthening: shot blasting strengthening, shot blasting strengthening of heat treated parts, shot blasting strengthening gear.

2. Steel wire shot peening: steel shot peening, steel sand blasting, ship shot blasting, steel shot peening, steel shot peening.

3. Steel wire shot cutting cleaning: shot blasting cleaning, shot blasting cleaning, die casting cleaning, casting shot blasting cleaning, forging shot blasting cleaning, forging shot blasting casting sand cleaning steel plate cleaning, steel cleaning, steel cleaning, H-beam steel cleaning, cleaning struktur baja.

4. Steel wire cutting dijupuk derusting: dijupuk blasting derusting, dijupuk peening derusting, casting derusting, forgings derusting piring baja derusting, forgings derusting, baja derusting, H-beam derusting struktur baja derusting.

5. Steel wire cutting dijupuk wedhi: perawatan wedhi.

6. Steel wire shot cutting pretreatment: coating pretreatment, coating pretreatment, surface pretreatment, ship pretreatment, section steel pretreatment, steel pretreatment, steel pretreatment, steel structure pretreatment.

7. Steel wire shot blasting: steel plate shot blasting, steel shot blasting, steel shot blasting.

Peralatan sing ditrapake kanggo motong kawat baja

Pemotongan tembakan kawat baja digunakake kanggo jalur produksi pretreatment baja, jalur produksi pretreatment baja, lini produksi pretreatment struktur baja, mesin shot blasting, peralatan shot blasting, peralatan shot blasting, mesin sand blasting, peralatan sand blasting abrasive.

Parameter teknis

| Produk | Cut Wire Shot | |

| C | 0,45~0,75% | |

| Mn | 0,40~1,20% | |

| Komposisi kimia | Si | 0,10~0,30% |

| S | 0,04% | |

| P | 0,04% | |

| Microhardness | 1.0mm 51~53 HRC(525~561HV) | |

| Intensitas Tarik | 1.0mm 1750 ~ 2150 Mpa | |

| Kapadhetan | 7,8 g/cm3 | |

Kategori produk